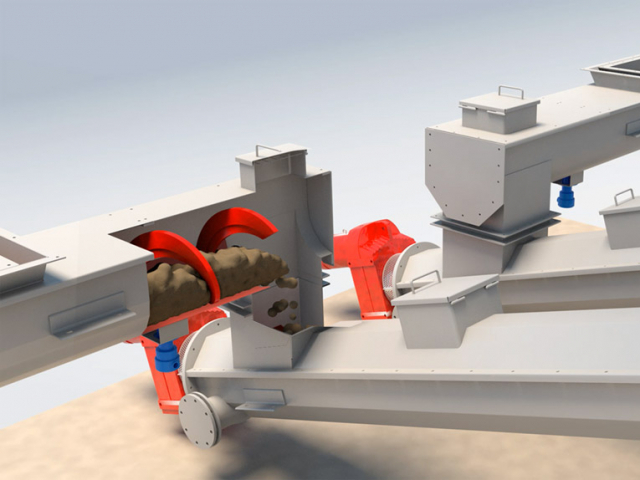

A large continuous operation cement plant was having problems with a shafted screw conveyor which fed sea-sand and slag into a ball mill.

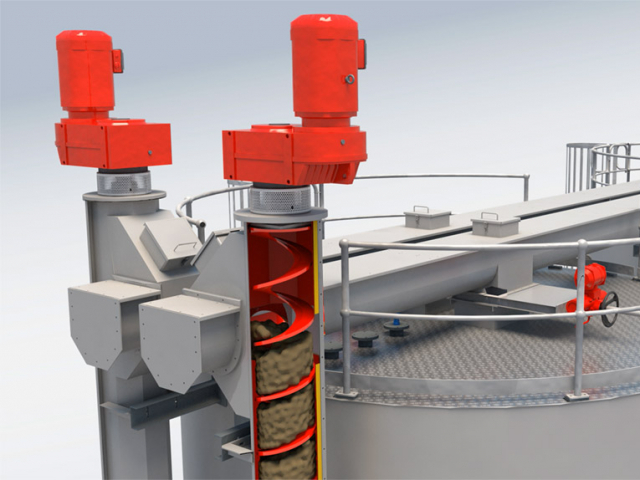

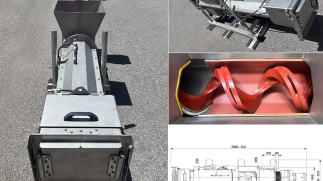

A build up around the shaft and at hanger bearing supports created frequent blockages and regular breakdowns and a short service life. SPIRAC was contracted to replace the shafted screw with two shaftless spiral conveyors to run in parallel, one conveyor to transport the sea sand, the other smaller conveyor to transport the slag. This "piggyback" configuration was possible due to the high fill rates and compact cross section of the shaftless spiral conveyors. The conveyor set fit nicely into the existing space with minimal disruption and modifications to the existing plant. The spirals ride on hardox wear bars, a common configuration for this type of abrasive operation. Operational since 2005, this arrangement has proven to be very reliable and requires near zero maintenance even in a hostile 24/7 service. A service life exceeding three years for wearbars and spirals has resulted in substantial maintenance cost savings and reduced downtime.